Production

Founded in 1983, Meditera today carries out the production, sales, and export of medical equipment with more than 700 employees. Our headquarter and production facilities are in Tire - Izmir. Production is carried out by injection, extrusion, and assembly within a 40.855 m2 campus of which 20.000 m2 is closed area and 5.000 m2 is clean room. Designs of products, molds and injection molds are made by R&D and engineering staff.

In addition, our joint venture S & MOHR America factory, established in 2019 with the know-how support of Meditera, produces respiratory systems in Mexico. S & MOHR America serves the medical device industry in Mexico, USA, and Latin American countries.

Meditera pays great importance to product development, innovative design, and new production techniques; supports continuous innovation and meets the current needs of the health care sector in its field and prepares for future needs.

Design, Molding and Assembly

Meditera pays great importance to product development, innovative design, and new production techniques; supports continuous innovation and meets the current needs of the health care sector in its field and prepares for future needs.

Design, Molding and Assembly

Supporting its product portfolio with wide and state-of-the-art molds, our facilities manufacture from granules to semi-finished products and final products with injection and extrusion machines.

Parts produced by injection and extrusion (semi-finished products) are assembled, packaged, and labeled in assembly lines at high quality standards.

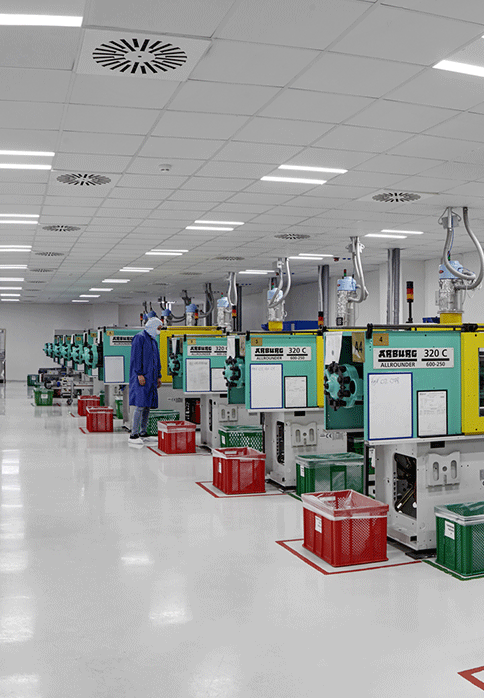

Clean Rooms

Clean Rooms

To keep the bacterial particle load to a minimum level, all our production, assembly and packaging processes are carried out in class 8 (100.000 Class) clean rooms that comply with the ISO 14644 standard.

Tailor Made Production

The contents of all breathing circuits including length, hose type, accessories (water traps, breathing bags, gas sampling lines, masks, filters, etc.) can be diversified in accordance with the clinic of healthcare professionals.

Disposable Medical Devices